To mark World Lab Day, we spoke to two of our Xperts to provide exclusive insights into our hardware lab.

Marcio and Benedikt discovered their passion for hardware during their studies. As software engineers, they are involved in developing the telematics applications for one of our major automotive projects. The applications are used worldwide on a daily basis and must be particularly reliable and have an extremely low susceptibility to errors.

In order to ensure top performance, we test our applications in our laboratory with the same hardware that is installed in the trucks. This is the so-called telematics box. The standardised technology platform makes it possible to integrate telematics systems in commercial vehicles and support functions such as vehicle tracking, vehicle diagnostics and communication.

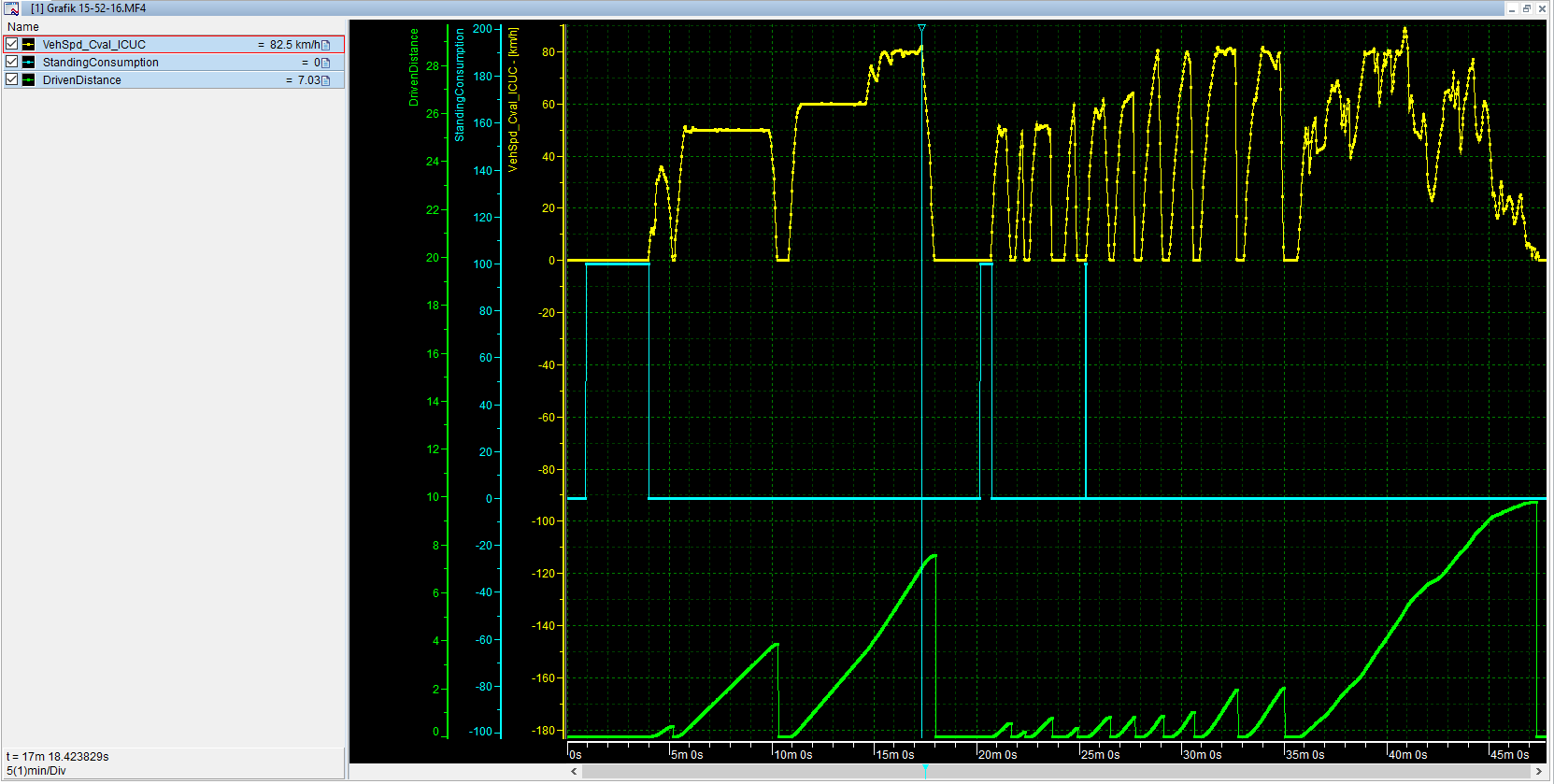

In our laboratory, we test these in a dashboard setup. Replays (recordings of real journeys) or simulations are transferred to the dashes via a computer, and the telematics box in turn sends the data to the backend. Basically, it's about comparing the expected values with the data sent, explains Benedikt. We use special software to determine the expected value, which is then visualised graphically. The special thing about this setup is that it enables us to actually test end-to-end, from the box that collects the data, to the server that processes the data and makes it available for retrieval, to the frontend that displays the data. The data that our Xperts work with here is not something you can just find on the internet, adds Marcio. Over the years, we have built up an in-depth understanding of vehicles through our project work. We can quickly derive recommendations for action from the results of our simulations because we understand them and react quickly to changes in the software.

Example Tool

Example Tool

There is a total of twelve such dashboards in our laboratory, which, although it is located within our premises, has full GPS and GPRS reception thanks to remodelling work. Even though most of the work can be done remotely, it is still sometimes necessary to be on site if, for example, a computer does not start up. The lab allows us to test our applications under conditions that would not be possible with simulated machines. It offers a test environment that comes as close as possible to the real world and thus helps us to meet the high requirements of our customers.

You can find more information about our innovative automotive projects here.